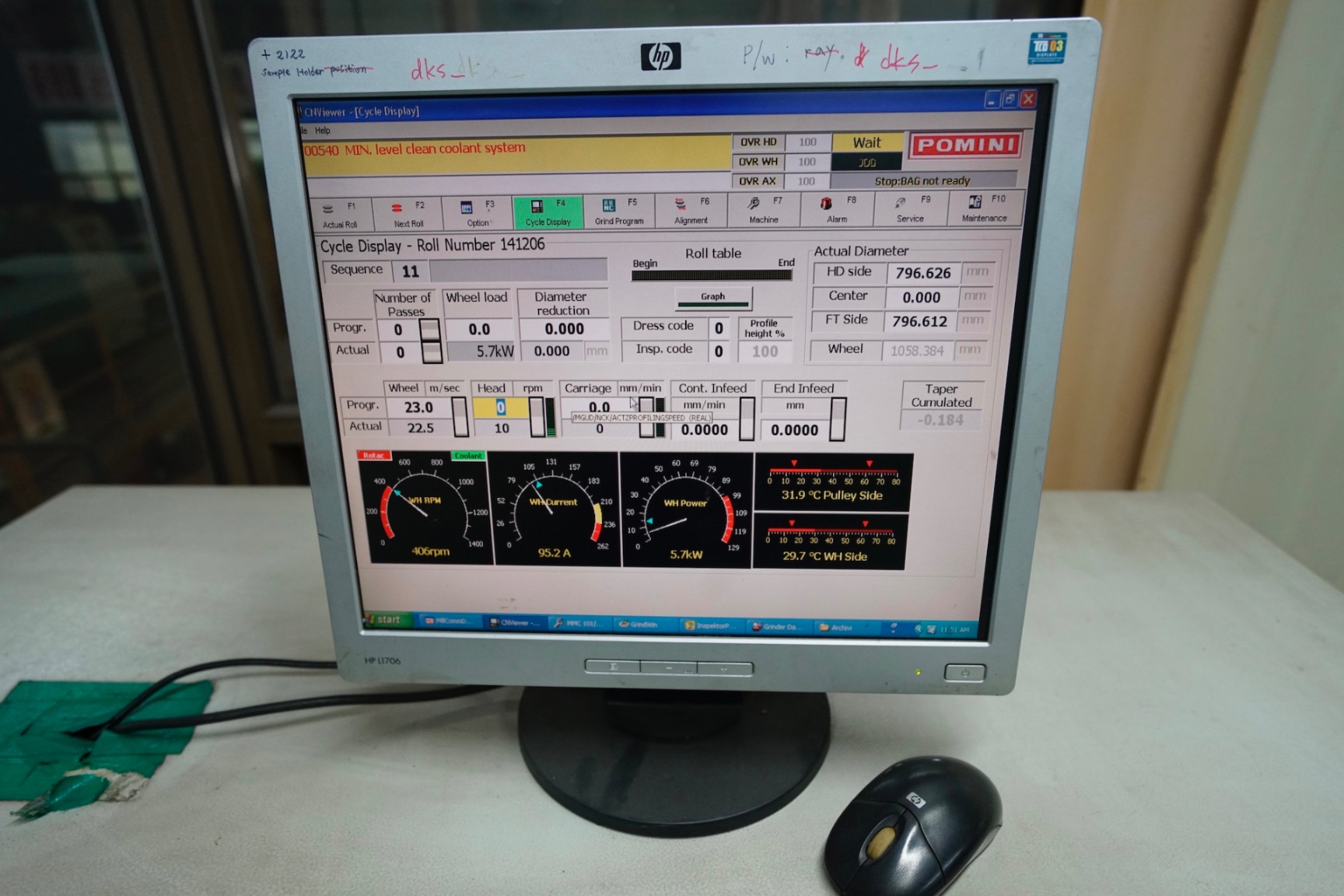

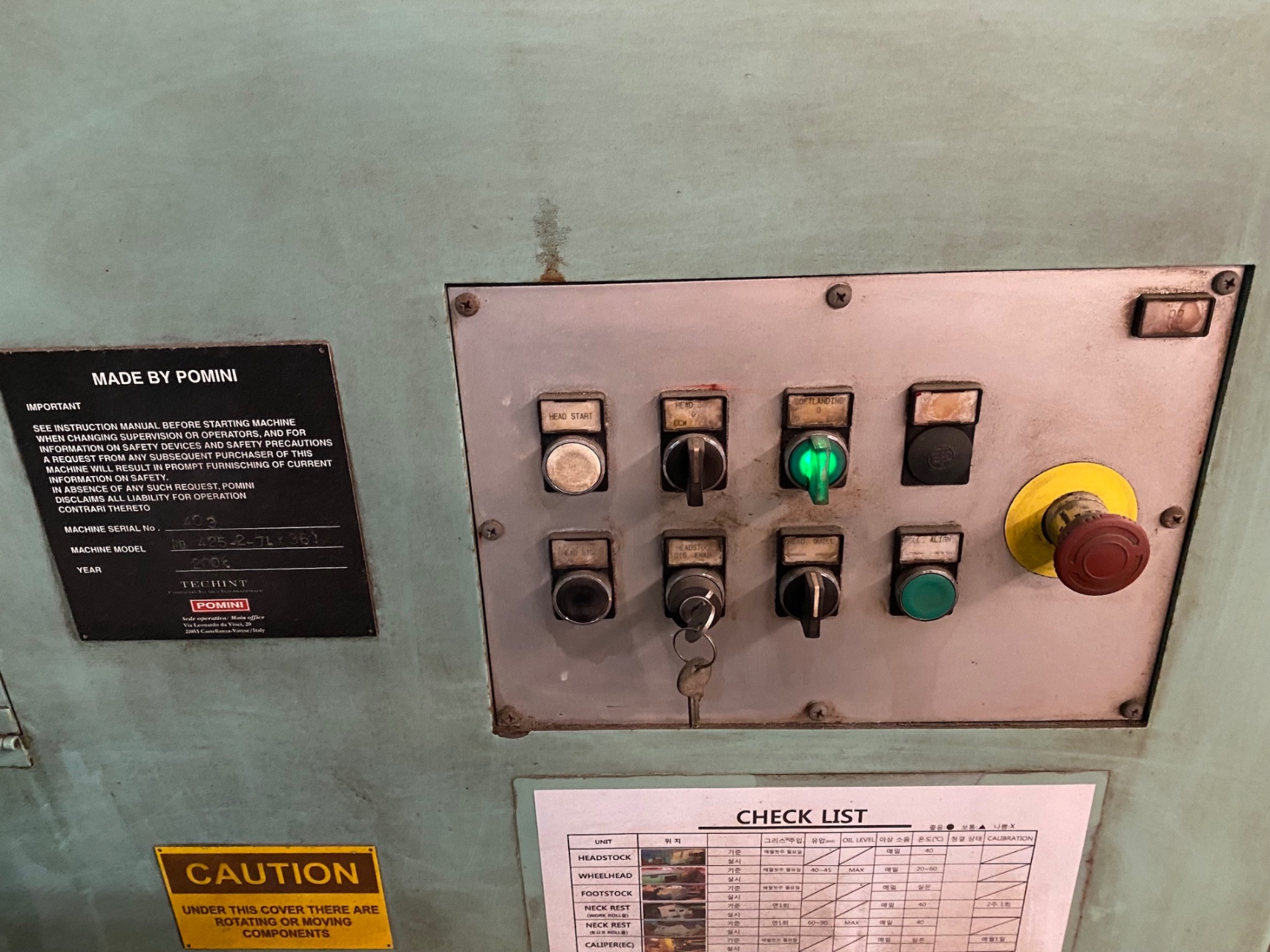

POMINI CNC Roll Grinder

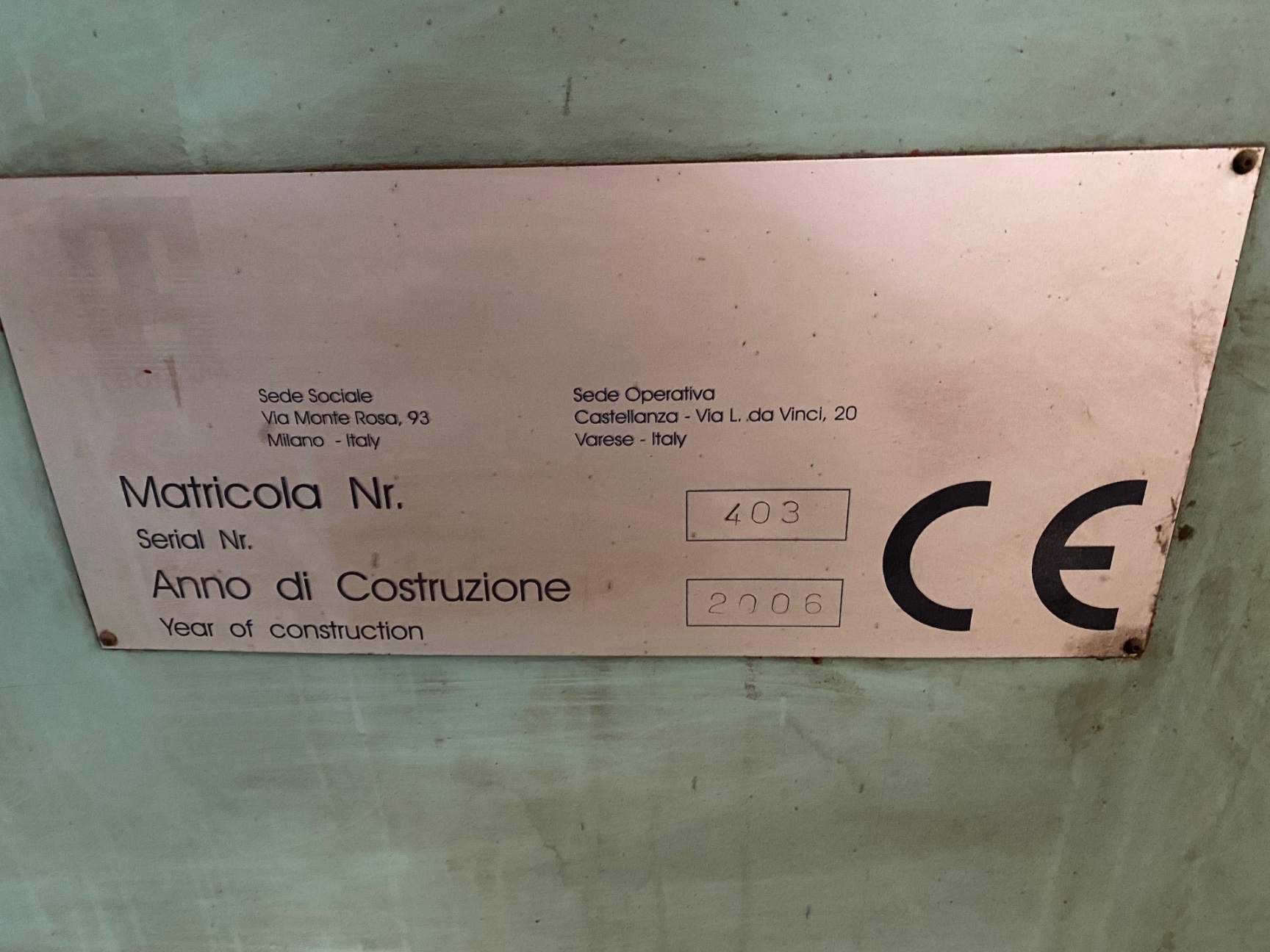

Model HD-425-2-7L

Siemens 840D, 12 Axes.

Built 2006.

Two flatbed system grinding and workpiece ways are separate.

Machine accuracy.

Straightness 0.001-0.002 mm/m.

Roundness 0.001-0.002 mm.

Excentricity 0.002 mm.

Profile for crown height up to 0.1 mm ±0.002 mm/m.

Surface finishing without chatter marks and no feed marks after finishing grinding stage.

On independent bed:

Auto Caliper Diameter 870 - 2.250 mm.

Eddy current crack and bruise detector probe.

Ultrasound depth Probe until 180 mm.

High Pressure wheel cleaner.

Wheel dynamic balancing electromagnetic automatically or manually.

Wheel dressing device with diamond.

2 Hydrostatic Steadies.

2 Hydrodynamic Steadies.

4 Soft landing for rools.

Wheel quick change device incl motor.

Jib crane.

Vibrations Measurement, recording on:

Headstock base

Neckrests

Footstock

Wheel head

Wheel head back

Carriage Lateral side.

Built 2006.

Two flatbed system grinding and workpiece ways are separate.

Machine accuracy.

Straightness 0.001-0.002 mm/m.

Roundness 0.001-0.002 mm.

Excentricity 0.002 mm.

Profile for crown height up to 0.1 mm ±0.002 mm/m.

Surface finishing without chatter marks and no feed marks after finishing grinding stage.

On independent bed:

Auto Caliper Diameter 870 - 2.250 mm.

Eddy current crack and bruise detector probe.

Ultrasound depth Probe until 180 mm.

High Pressure wheel cleaner.

Wheel dynamic balancing electromagnetic automatically or manually.

Wheel dressing device with diamond.

2 Hydrostatic Steadies.

2 Hydrodynamic Steadies.

4 Soft landing for rools.

Wheel quick change device incl motor.

Jib crane.

Vibrations Measurement, recording on:

Headstock base

Neckrests

Footstock

Wheel head

Wheel head back

Carriage Lateral side.

Working Capacity.

| Grinding length | 11.000 mm |

|---|---|

| Max diameter with 1.066 mm Grinding wheel | 2.200 mm |

| Min diameter with 1.066 mm Grinding wheel | 800 mm |

| Center distance | 11.700 mm |

| Max Roll weight | 80 Ton |

| Max Roll weight with Steadies | 180 Ton |

| Min distance between wheel center and roll axis | 845 mm |

| Max distance between wheel center and roll axis | 1.635 mm |

Carriage Axis Z, Hydrostatic

| Feeds, Infinitely variable | 0-6.000 mm/min |

|---|---|

| Oil film thickness | 0,020 mm |

| Distance between carriage ways | 1.500 mm |

| Ways width | 160 mm |

| Total length of the carriage on ways | 3.385 mm |

Wheelhead on Carrige Axis X, Wheel Probe Axis A, Inspektor Axis A1,

| Wheelhead cross travel Ballscrew, Axis X | 940 mm |

|---|---|

| Resolution axis X | 0,0001 mm |

| Wheel Spindle length | 1.695 mm |

| Spindle bearing, hydrostatic, diameter | 254 mm |

| Resolution Infeed micrometer handwheel, Axes X | 0,00001 mm / division |

| Continuous wheel infeed, U axis on radius | 0 - 0,35 mm/min |

| Rapid wheel indeed, axes X | 0-830 mm/min |

| Wheel motor, AC | 130 kW |

| Wheel Speed | 400-1.100-1.600 rpm |

| Wheel Cutting Speed | infinitely variable |

| Surface speed wheel diameter 1.066 mm | 45 m/sec |

| Surface speed wheel diameter 670 mm | 45 m/sec |

| Wheel hole, diameter | 508 mm |

| Wheel thickness | 76 - 152 mm |

| Wheel diameter | 670 - 1.066 mm |

Crowning, Axis U.

| Max crown on the diameter | 10 mm |

|---|---|

| Max concavity on the diameter | 10 mm |

Headstock

| Workpiece rotating speed | 5 - 50 rpm |

|---|---|

| Headstock motor | 200 kW |

| Max transmissible torque | 76,5 kNm |

| Faceplate control system | V Belts |

| Max Centre diameter, metric type | 160 mm |

| Stroke of Quill | 150 mm |

| Length of headstock | 3.110 mm |

Tail stock

| Quill diameter | 260 mm |

|---|---|

| Stroke of quill | 750 mm |

| Maximum centre diameter, metric type | 160 mm |

| Taper | Metric 5% on the diameter |

| Tailstock length | 1.300 mm |

| Stroke of tailstock | 8.000 mm |

Caliper, Arm Axis C, Carriage Axis V, Rotation Axis B.

| Max measurable diameter | 2.250 mm |

|---|---|

| Min measurable diameter | 870 mm |

Machine Dimensions.

| Machine weight | 130 Ton |

|---|---|

| Length | 19,5 m. |

| Width | 5,5 m. |

| Height | 3,2 m. |

| Foundation depth | 3,8 m. |